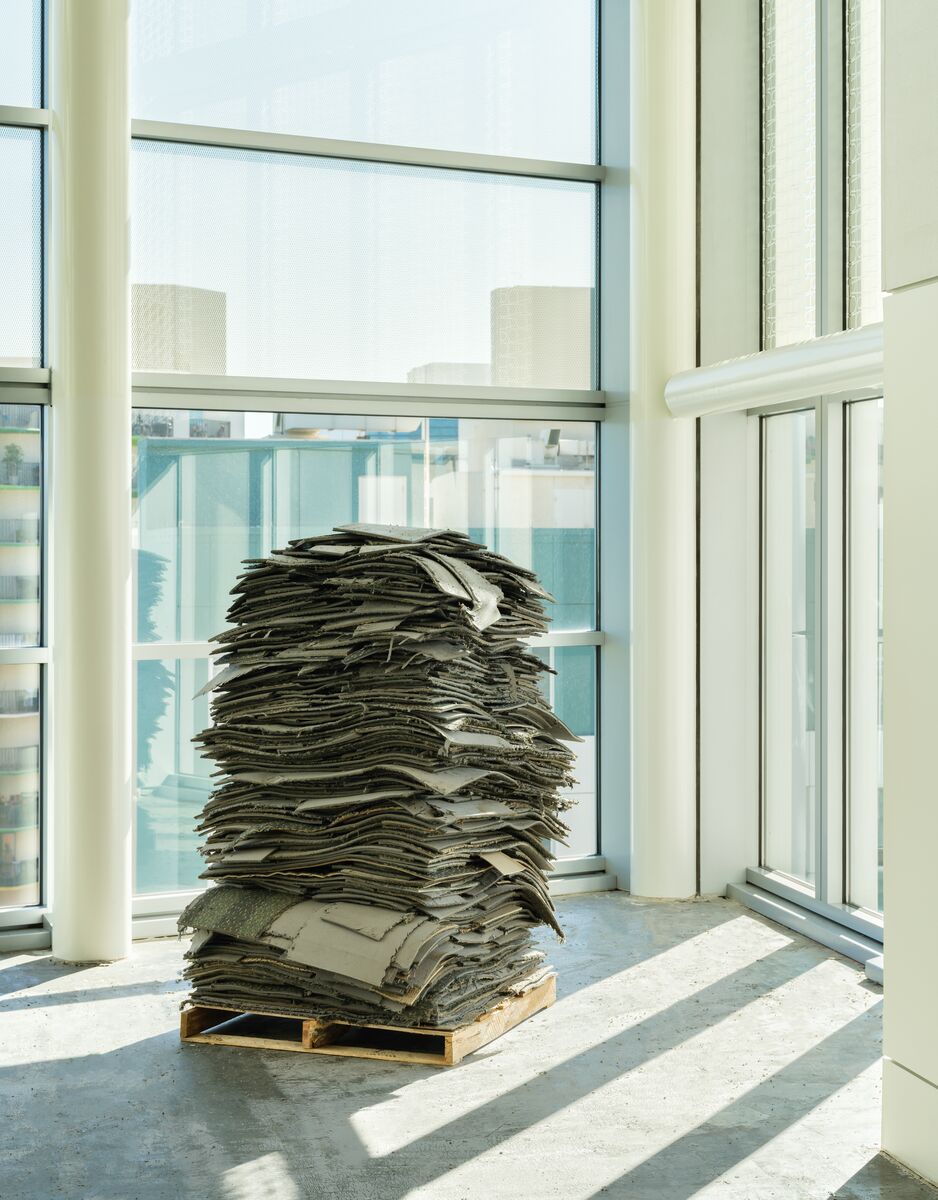

Old carpet, new life. Broadloom carpet once destined for landfill is being transformed into reusable materials and innovative biobased resources through a partnership between Tarkett® and Flooring Foundation.

The systems established by Tarkett’s SourceOne® turnkey service program and its ReStart® take-back and recycling program laid the foundation, but those systems are only as strong as the partners who support them.

Carpet is one of the most common design elements in corporate interiors—and one of the most frequent contributors to landfill waste. For decades, the end of life for broadloom and carpet tile was simple: cut it up, load it in a dumpster, and send it away. But what if those old floors could have a second life?

Across the industry, innovators are proving that they can. Tarkett’s ReStart® take-back and recycling program is pioneering new ways to reclaim and recycle old flooring, turning waste into resources. At the heart of these efforts are countless unsung heroes—flooring contractors who are rolling up their sleeves, working with the manufacturer to establish new processes, and setting examples for what circularity looks like in action.

Building a New Model for Flooring Reclamation

For years, Dave Knaub, owner of Flooring Foundation in New Jersey, had been removing carpet as part of routine renovation projects. The process was straightforward but wasteful: pull it up, haul it out, throw it away. That changed when sustainability leaders, along with his partnership with Tarkett, inspired him to commit to a better way.

As a longtime supplier with Tarkett’s SourceOne division, providing turnkey services for deinstallation, reclamation, and installation for major accounts, Dave was no stranger to the company’s ReStart program. He’d also worked closely with Rachel Palopoli, Tarkett’s director of circular economy, and the two had frequent conversations about how to reduce construction waste and their personal commitments to living and working more sustainably. After a few months of planning, Dave took what he knew about flooring recycling, worked with Rachel to refine a few details, and built recycling into a fully integrated service model for all his clients. Today, he offers recycling as a standard component of his contracting services and recently expanded his business with a dedicated reclamation facility, where deinstalled materials are staged, stored, and sorted for their next life. For anything that can’t be reused, he knows that Tarkett’s ReStart program will likely have a solution.

“It’s about more than removing carpet. It’s about making sure it gets somewhere it can do good, instead of ending up in the ground.”

– Dave Knaub, Owner of Flooring Foundation Corp

Creating Value Through Reuse

Not all carpet pulled from an office space is ready for the recycling stream. Much of it can be reused outright, extending its life in creative ways.

Dave and his team have found strong demand for high-quality, second-use flooring products in settings like apartment buildings, where owners accustomed to lower-grade broadloom are thrilled to find premium carpet tile at a fraction of the cost. For corporate clients, reclaimed carpet often finds its way into back-of-house areas, keeping the most visible spaces fresh while ensuring nothing usable goes to waste.

This growing reuse market isn’t without challenges. Once a pallet of reclaimed carpet is gone, it’s gone—making proactive inventory management and close collaboration with specifiers essential. But the payoff is clear: on a typical project, up to 40% of carpet can be reused, and in some cases, the reuse rate reaches as high as 60%.

Partnership Is the Key to Removing Barriers

The success of these takeback initiatives depends on more than just one stakeholder. Contractors like Dave play a central role, but architects, designers, and manufacturers all have to work together to make circularity practical.

Dave has quickly been able to train his team to identify which materials can be recycled back to the manufacturer, which can be cleaned and reused, and which need to move through alternative reclamation streams. The result is a cost-neutral approach: when Dave manages both deconstruction and installation, reclamation comes at no added cost to the client—removing the common excuse that “it’s too expensive to recycle.” Dave shared, “By integrating reclamation into our services, we’re removing the barriers for clients. It costs no more than a dumpster but delivers so much more value.”

For architects and designers, that partnership is critical. They can specify new Tarkett products for front-of-house spaces while reserving reclaimed materials for back-of-house areas, ensuring clients get both design impact and sustainability wins.

Innovation Spotlight: The Various Paths to Circularity

For flooring that isn’t suitable for reuse, Tarkett has several recycling options through its innovative ReStart program, depending on the material. As the company shares, every type of material has its own path to circularity, and Tarkett is actively innovating solutions for each of its product categories. For example, Tarkett’s ethos® carpet tile backing now has a closed-loop circular solution, meaning the backing of every ethos carpet tile collected through ReStart is recycled into new ethos carpet tile backing. Through a partnership with Avery Automats, all vinyl sheet and tile products collected through ReStart become raw materials for new automotive products. And now through the power of mushrooms, reclaimed broadloom and Powerbond® hybrid carpet are transformed into new biobased raw materials, which is slated to be used in future Tarkett products. Recently, Dave and Rachel partnered to take old broadloom carpet out of a global financial institution and, through ReStart, the material is being processed using this technology.

Each of these approaches underscores Tarkett’s commitment to forging new paths to circularity, proving that even the most stubborn materials can be reimagined when companies partner with each other around shared values.

A Changing Landscape of Legislation

These efforts are not happening in isolation. Across the U.S., lawmakers are beginning to require manufacturers and contractors to take responsibility for flooring at end of life. Due to legislation requirements, California’s carpet recycling rate now hovers above 40%, compared to less than 5% in most of the country. In New York, a new extended producer responsibility (EPR) law is slated to take effect in 2026—and Dave’s company is ready to support it.

For designers working in corporate interiors, this is a glimpse of the future. Circularity won’t be optional – it will be expected. Tarkett’s ReStart program, and the contractors already embracing it, are building the infrastructure today that will make compliance tomorrow both achievable and cost-effective. According to Dave, “This work has opened doors I never expected — from architects to Fortune 500 sustainability officers. Circularity is no longer a side conversation, it’s the future.”

The Human Side of Sustainability

For Dave, the work goes beyond compliance or even innovation. It’s about pride. “It feels fantastic to know we’re keeping this material out of landfills,” he says. “It validates all the extra effort.”

That extra effort—stopping to palletize old carpet rather than tossing it—is what makes the difference. Small actions, multiplied across projects and partners, create the systemic change needed for the industry to truly close the loop.

“We’re proving that circular economy solutions don’t just work in theory – they work at scale, and they work today.”

– Dave Knaub, Owner of Flooring Foundation Corp

Looking Ahead

Every year, Flooring Foundations and SourceOne divert hundreds of thousands of pounds of carpet from landfill. With new partnerships forming, legislative drivers accelerating, and Tarkett continuing to pioneer next-generation recycling technologies, that impact is only set to grow.

Circularity in corporate interiors isn’t a dream for the future—it’s already happening. And it’s happening because contractors, designers, and manufacturers are choosing to work together.

Tarkett is proud to lead this movement by investing in innovation and collaborating with partners across the industry who help make the concept of circularity a reality on the ground.

Learn more about how Tarkett is leveraging the power of partnership to reshape the future of flooring.

Take the Next Step

Learn More | Connect with a Rep | Earn CEU Credits

This article was created in partnership with Tarkett.

Images courtesy of Tarkett.

Learn More

Tarkett’s ReStart® Recycling Program: Keeping Old Flooring Out of the Landfill