Recently, circularity professionals from around the world convened in Denver for the annual Circularity conference, bringing together over 1,100 attendees from fields such as corporate strategy, sustainability, product design, manufacturing, sourcing, finance, and logistics, among others. WDM’s Cynthia Milota was also there and is now sharing her insights and the latest thinking on circular strategies for the built environment.

Local matters. Many of the presentations focused on projects that started small, in the neighborhood and then scaled to something much more.

Before we get to the trends and insights, let’s just say that there was excitement and optimism in this global crowd. Twenty one countries were represented including New Zealand, South Korea, Malaysia, Egypt and Sri Lanka. Work is happening locally and nationally on initiatives focused on reducing cost, increasing efficiency, diverting waste, and innovating in all sectors. Many teams continue to make progress under the radar amidst political uncertainty, taking the long view and not necessarily broadcasting all their achievements.

Progress is not linear. We are distracted by political head winds, but we must keep the gas on innovation, as setbacks are proving grounds for progress.

– Joel Makower/Chairman Trellis Group

Challenge Accepted!

As in previous years, Circularity was über sustainable, as in “being a superlative example” rather than the car sharing service. Working with replenysh, the software platform to recover and reuse materials for businesses, Trellis the conference organizer, set an aggressive goal to divert materials collected at the event from the landfill. Front-of-house collections and sorting were source-separated by attendees. Back-of-house collections and sorting included stations set up for compost, materials sorted and picked up through out the day, with all materials being weighed every evening.

The Result? The event collected 10 streams of recyclables with over 1500 lbs. of materials recovered. A whopping 674 lbs. of food was donated to local food banks and over 900 lbs. of food was composted.

Want More?

Scan this QR code or click here to access the replenysh “Real Time Impact Report” on the Circularity conference.

3 Circularity Conference Themes

Presentations and conversations centered on three themes:

1) what the built environment can learn from the consumer products industry

2) building deconstruction can make economic sense

3) new waste diversion strategies

Here’s a summary of what you should know from the conference.

1. What the Built Environment Can Learn from the Consumer Products Industry

In the consumer product’s space, waste is in the hands of the consumer. In the workplace, however, waste management is in the hands of the tenant, their facilities team, the landlord and the municipality.

There is legislation called Extended Producer Responsibility (EPR) in several US states. In this concept, “brands are now required to pay fees based on the volume and type of packaging they introduce into the market, and the funds are then used to pay for the collection and recycling of packaging waste,” (Dayton, 2025).

In some states, like CA, EPR programs are extended to include consumer items such as mattresses, carpets, batteries, textiles and paints, Cal Recycle. However, for commercial built environment products, there are no national US EPR regulations, yet. In France the building industry has had EPR legislation since 2020 with France’s Anti-Waste for a Circular Economy Law.

Defining the Term: Extended Producer Responsibility (EPR)

This is the concept where the manufacturer or the brand owner takes operational and/or financial responsibility for a product and/or its packaging at the end of its useful life.

Global furniture manufacturers such as Steelcase, MillerKnoll and Haworth, each offer their own version of compliance with EPR legislation in jurisdictions where applicable, with packaging recycling, and end-of-use programs such as reselling, refurbishing, donating and diverting product from landfills. But we could do better.

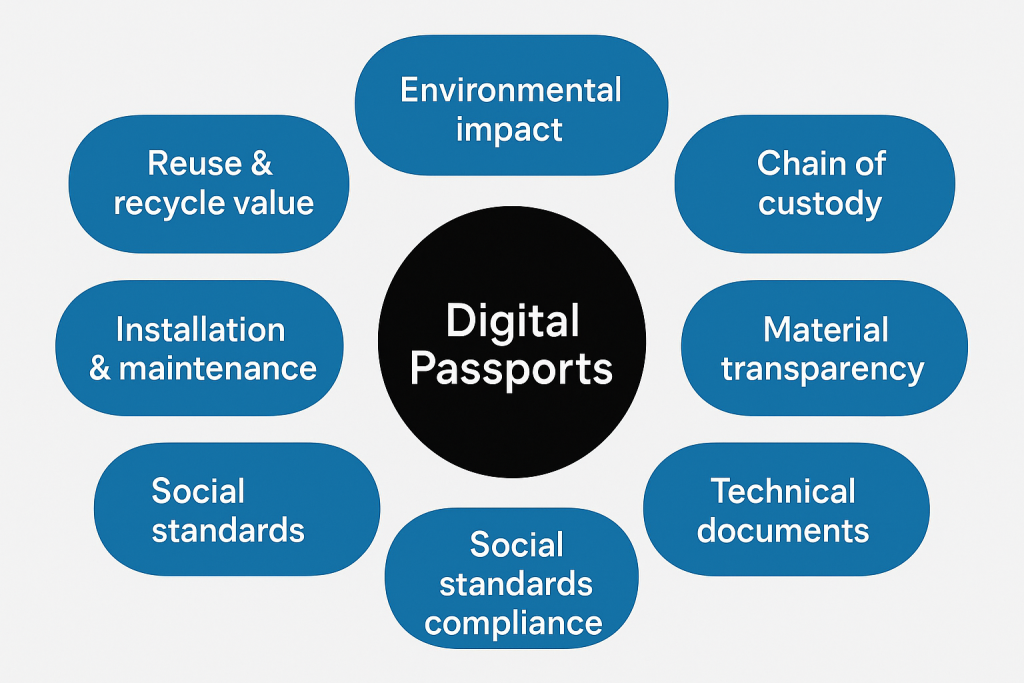

While not mandated yet, the US consumer products industry has been developing Digital Product Passports as a tool to provide information on products, including early adopters in luxury fashion and jewelry, but also electronics, batteries, textiles/footwear, automotive and construction materials.

Defining the Term: Digital Product Passports (DPP)

A digital tool for collecting and providing product data including material content, performance, environmental impact, transportation, storage, installation, maintenance, repair and end-of-use data for use by producers, consumers, regulatory bodies and the resale market.

Example of their content:

Novalis Innovative Flooring, a global LVT (luxury vinyl tile) flooring manufacturer has partnered with an online database of digital materials to house its Digital Product Passports providing access to all product information. With the entire lifecycle of the product in mind, the Novalis team has developed a QR code that is printed onto the back of all of its products.

Want More?

Check out this QR code for an example of a Novalis Digital Product Passport.

Watch this 2 minute video from Circularise on DPP’s.

2. Building Deconstruction is Already Happening and Here’s Why

The commercial building industry has been experimenting with deconstruction of buildings for the past decade. And it was difficult to make the process economically feasible, until now.

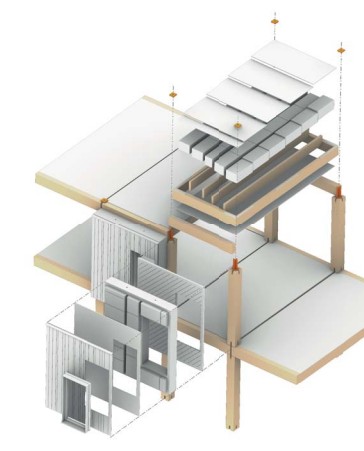

Defining the Term: Deconstruction / Strategic Dismantling

Selective dismantling of a building’s components for reuse, repurposing, recycling and waste management. Recovered materials are “harvested waste” reclaimed into useful building products.

To the critics who say that deconstruction takes longer and costs more, yes, on the surface deconstruction does cost more, reports Emily Freeman, Policy Advisor/Circular Economy at City of Boulder. However, the hidden costs of demolition must be factored in, such as wasteshed costs, the sheer volume of construction debris, (one house might be the landfill equivalent of 6 months of one community’s household waste), tipping fees and additional costs to ship to more remote landfills.

When the resale value of materials and the tax benefits of the material donations are calculated into the equation, deconstruction starts to make financial sense. The environmental impacts of landfill diversion and the specialized jobs created are two additional intrinsic benefits.

Defining the Term: Wasteshed

An area of the state that has a common waste disposal system, where landfills are shared by multiple communities.

Currently Environmental Product Declarations (EPDs) are not required for building materials, including salvaged ones, but “their use is rapidly growing in line with awareness about environmental impacts, (of using salvaged materials). Both public and private stakeholders are increasingly demanding EPDs,” (Zacharia, 2025).

Defining the Term: Environmental Product Declaration (EPD)

A document that communicates the environmental performance or impact (positive or negative) of a product or material through its entire life cycle, designed to be a tool to compare various product options.

Three cities in the US have deconstruction ordinances: for commercial buildings San Antonio and Boulder; for residential properties Portland. And Vancouver and Boulder are exploring new policies that will integrate DfD (Design for Disassembly) features which build in planning for disassembly from the start.

Defining the Term: Design for Disassembly (DfD)

The design of buildings to accommodate future changes and dismantling, ensuring the components and materials can be re-used, recycled or repurposed.

The goal of all this legislation is not to just downcycle materials but to recapture for future use. With the enormous amount of construction waste, strategic dismantling of buildings supports both economic competitiveness and environmental goals.

Defining the Term: Downcycling & Upcycling

Downcycling is converting materials and products into those of lesser value or quality than the original, (e.g. wood chipped for mulch or biomass fuel).

Upcycling is creatively reusing materials to create new products of a higher value than the original, (e.g. glass bottles into lamps or salvaged wood into decorative partitions and furniture).

Want More?

Watch this 2 minute video from the City of San Antonio on Deconstruction

3. Waste Diversion Strategies You can Use

The average American generates approximately 4.4 pounds of waste each day, and of that, about 2 pounds per day is generated at the office. “According to a study by the United Nations, business waste accounts for approximately 20% of the world’s waste, with offices being a significant contributor (Sy, 2023).”

Waste is only garbage when you call it that.

Using waste as a strategic and economic advantage was the call to action in several presentations. Waste is operational inefficiency.

Waste management best practices presented by Kristin Steiner/Republic Services center around these four strategies:

- Know where your materials come from: work with procurement and supply chain to design waste out of the system.

- Prioritize your heaviest opportunities: target materials that will move the needle on diversion.

- Build the business case: determine the optimal equipment and handling needed to maximize returns.

- Foster a zero-waste culture: educate staff, appoint a champion, celebrate wins.

Conducting assessments such as waste audits, site specific and procurement reviews are a place to start. Building a strategy which includes waste optimization roadmaps, peer benchmarking and business case development can be formulated with the assessment data. Implementing plans target hard to divert waste streams, employee training, custom facility signage and onsite material segregation, (Steiner, 2025).

Empowering functional roles in a zero waste strategy involves asking questions like:

- What do you need to be successful in reducing waste?

- How can we revise our procurement contracts to reduce waste?

- How do we attract clients or enhance our brand by incorporating things like reusable products and compost food waste?

- How do we make waste sexy, like making art from waste, or including upcycled clothing on our website?

- How do we partner with our vendors, recyclers and waste haulers to reach our goals?

Dealing with waste is a change management exercise and zero waste is a team sport, including everyone from janitorial, operations to procurement.

– Kristen Royal/MGM Resorts

Notables from the Exhibit Hall

From the Circularity expo hall, WDM was impressed with Spare-it, the first in-building waste metering platform for organizations to measure, report and manage waste. Their Waste Intelligence secure system combines Wi-Fi-free scales and AI-powered photo analysis to reduce waste, streamline sourcing and drive resource and cost savings.

Check out this Spare-it video @ Boston University.

Another strategy to jump start your workplace recycling program is to use Terra Cycle Zero Waste Boxes. ™ There are options for everything from candy/snack wrappers to coffee capsules, and all manner of kitchen and office waste. This simple all-in-one solution will help your office recycle almost anything, offering various size collection boxes and pre-paid shipping labels.

Check out this Terra Cycle Zero Waste Box short interview.

Closed Loop Material Cycles and Bill McDonough

Bill McDonough, co-author of Cradle to Cradle, (2002) is an architect and a leader in sustainable development and design. His design philosophy, to integrate closed loop material cycles into the design/ building and operation of architecture, was incorporated into many notable projects including the Herman Miller Green House (1995), the Ford River Rouge Complex (2002) and the Method Manufacturing Facility (2015).

Considering his impact and legacy in the circular space, when asked how to get started, he suggested that the first move should be to understand and optimize what already exists, do some assessment and re-arrangement. And then, maybe build new. McDonough said knowing the truth is hard, but finding the truth is harder.

Defining the Term: Closed Loop Material Cycles

In these sustainable systems, materials and products are reused or recycled infinitely, minimizing waste and maximizing resource utilization. It’s a circular economy approach where materials return to the production cycle instead of being discarded.

Regenerative Economies are Nothing New

One of the most impactful, uplifting, and significant keynote speakers was Dr. Lyla June, an indigenous scientist, community organizer and public speaker of the matrilineal clan of the Diné Nation. She presented three “strategies native peoples from around the world have used to work with nature, expand habitat and design for perpetuity,” (June, 2023). In these indigenous food and land management techniques humans have an essential ecological role.

Ancient solutions to modern problems

Tenochtitlan, was the ancient capital of the Aztec empire, located on the site of modern Mexico City. It was a zero waste city, with advanced agriculture, strategic water management, and floating gardens for food. There was no waste, with everything including human waste being recycled for gardens and tanning leather.

The Mebengokre (Kayapo) indigenous peoples of the Brazilian Amazon, use soil management strategies that combine compostable debris and controlled burns to release nutrient dense ash and sustainable pyro-adapted grasses. These minerals act as a natural fertilizer for planting various crops together to protect the soil from torrential rain and scalding sun.

On an island off the central coast of British Columbia, the Hailzaqv Nation have been protecting the herring roe harvest with the same strategies for 14,000 years. Hand planting hemlock and kelp forests into the waters offshore provide a habitat for herring to lay their eggs, sustaining native populations and cascading up the food chain nourishing bear salmon, eagles, wolves and humans.

Indigenous eco systems are not a native American thing, they are a human thing.

– Dr. Lyla June, 2025

Keep Calm and Carry On

Attendees of the Circularity conference in Denver are meeting the moment, being aggressively incremental, making progress and embracing the concept that less bad is not good enough.

In all the presentations and expo products, we saw this notion of perpetual products, the end of one useful life is the start of the next useful life. That is the essence of the circular economy. There is no waste in the system.

Plan Ahead

Next year Circularity will combine with VERGE/ where climate meets technology, bloom / where biodiversity meets the bottom line and GreenFin / where capital powers the clean economy, locating all four events in one location, San Francisco, June 23-25, 2026. We hope to see you there!

Bonus Content: Want More?

- Catch up on last year’s Circularity 24 conference held in Chicago

- Watch the Circularity Keynote presentations with the links below:

Tues April 29, 2025:

Speakers: Phoebe Yu/Replenysh; Jon Smieja/Trellis; John Warner/The Technology Greenhouse; Asha Singhal/Biomimicry Institute; Lyla June/Orator-Scientist-Dreamer; William McDonough/McDonough + Partners.

Wed May 1, 2025:

Speakers: Joe Macleod/AndEnd; Andy Ruben/Trove; Hana Kajimura/Trellis; Deanna Bratter/Crocs; Brian Lewis/Trellis; John Williams/Waste Well; Jeannette Felix/Homeboy Industries.

Images courtesy of Cynthia Milota unless otherwise notes.

References

Dayton, E. (May 2025), “New Packaging EPR Laws,” Retrieved from: Amidst all the attention on this administration’s rollback of federal… | Eric Dayton | 27 comments

Freeman, E. (May 2025), personal communication.

June, L. (June 2023), “3000 year old solutions to modern problems,” Retrieved from: https://www.youtube.com/watch?v=eH5zJxQETl4

Steiner, K. (May 2025), personal communication.

Sy, J. (April 2023), “A Guide to Office Waste: Facts, Figures and Tips for Reduction,” Retrieved from: https://www.unsustainablemagazine.com/guide-to-office-waste-facts-figures/

Zacharia, M. (March 2025), “A Simple Guide to EPDs,” Retrieved from: https://oneclicklca.com/en-us/resources/articles/guide-to-epds